GENERAL INFORMATION

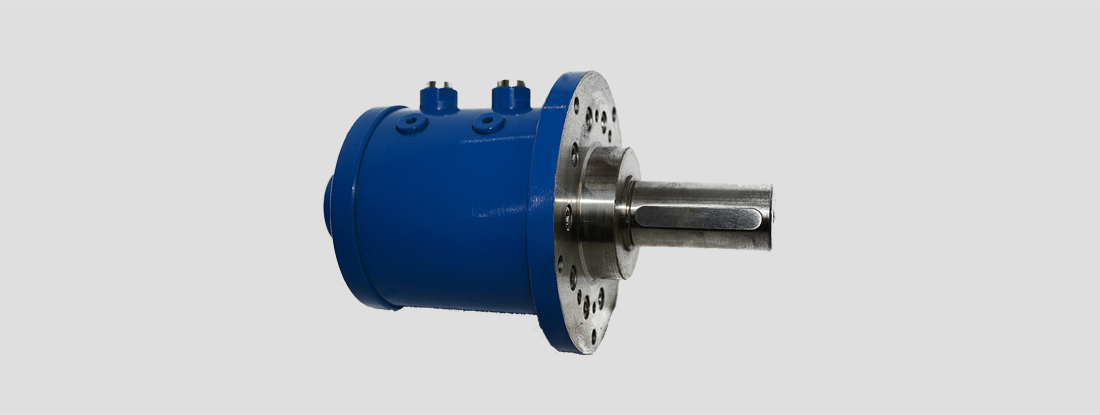

The ZD series piston screw engines are designed for operating pressures up to 100 bar. They feature a compact cylindrical shape and can be used in all industrial applications where there is a need to realize high-torque rotary motion in limited space.

OPERATING PRINCIPLE

Thanks to the counter-directional threads between the cylinder base, the piston and the output shaft, the axial movement of the piston is transformed into a net rotational movement of the output shaft.

If you look at the output shaft, the direction of rotation is to the left when the front connection is filled with pressure fluid.

OPTIONS

Actuators in this series can be offered in special configurations with infinitely variable rotation angle control, drive shaft or end-of-stroke braking.

DESIGN

The output shaft, piston and cylinder are the most important parts of a piston screw rotary engine. The drive mechanism parts are equipped inside and outside with multi-way counter-directional threads. The moving parts are made of high-strength hardened material.

Rotational symmetrical seals guarantee leak-free operation and, thanks to shut-off valves, ensure locking under load in any position. The ZD series is distinguished by its compact shape, which allows it to be used in extremely limited installation space.

BRAKING AT THE END OF STROKE

Piston-screw rotary motors can be equipped with an end-stroke braking device. The braking effect can be adjusted smoothly and precisely as required using the throttle check valve. The supplied hydraulic fluid opens the check valve and acts unimpeded on the piston surface.

TECHNISCHE DETAILS

- Execution

- Size table

- Typical designations

- Working torque pressure

- Standard “O” design with end mounting

- Drive shaft and cam disc “SW”

- Stepless control “WV”

- Flange mounting “F”

- Specifications

Do you have any questions about our products?

Write to us or simply give us a call!

Email: paul.rudi@voss-antriebstechnik.de

Tel: +49 5251 683 408-2